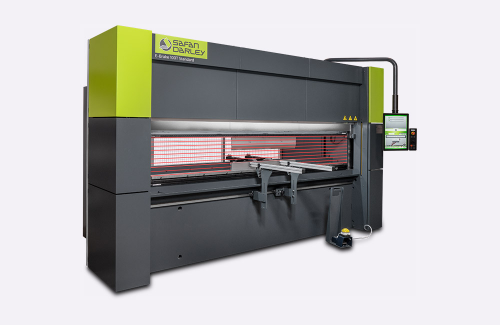

The first electronic press brake for heavy-duty work

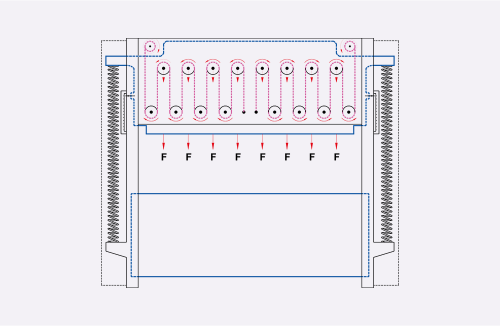

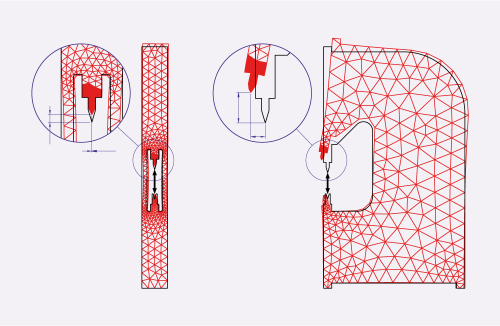

The SafanDarley E-Brake 'Dual Drive' 300T now makes the unique advantages of the E-Brake technology available in the heavy segment of pressure forces up to 330 ton. This breakthrough was possible only thanks to a new SafanDarley invention: the 'Dual Drive' with a double pulley system. Together with the newly developed bearer and the new E-Control Touch Screen control, this results in an unprecedented increase in performance in the heavy segment.

You will have a much stronger position in the market with the new SafanDarley electronic heavy-weight. You can produce the most accurate and constant bending angle across the entire 13 ft range of the machine without the need for crowning. Faster, uses less energy, more ergonomic and durable than any other hydraulic press brake.

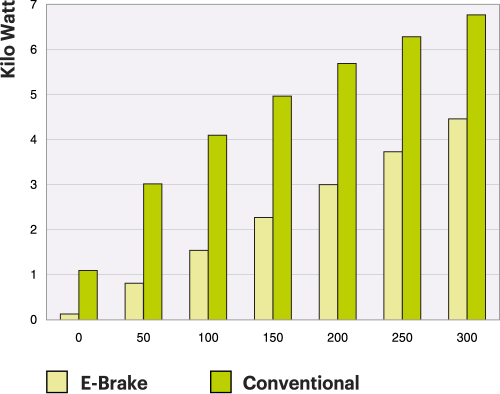

Up to 30% higher productivity

Up to 50% energy saving

No harmful hydraulic oil, low CO2 emissions

Noiseless operation

Full working length backgauge

User friendly touch screen control

Key Features

Technical Data

| Model | 300-4100 |

|---|---|

| Pressure force in US Ton | 330 |

| Bending length in inches | 160 |

| Maximum stroke in inches | 16 |

| Q size in inches | 27 |

| Closing speed in inch/min | 213 |

| Bending speed max. in inch/min | 48 |

| Return speed in inch/min | 213 |

| Motor power in kW | 30 |

| Machine weight in lb | 48.5 |

| Machine length in inches | 216 |

| Machine height in inches | 135 |

Standard equipment

SafanDarley EC20 Touch Screen CNC press brake controls

1 Hold to Run operating console

CNC-controlled R-axis

CNC-controlled Y1-Y2 axis (top beam adjustable inclined +/- 0.1 inch)

CNC-controlled back gauge (X-axis) with a wide range

Manual adjustment of 2 back gauge fingers across a linear parallel guide

Daylight of 27.16 inch (Q-dimension)

NSCL II MC Premium top tool mechanical clamping system

NSCR II MC Premium with CNC crowning

2 Support arms (11.81 inch)*

Programmable and integrated safety light guard*

Safety in compliance with CE*

* Standard only for CE countries

Options and Product Enhancements

Control

|

SafanDarley EC 20 | touch screen CNC press brake controls |

|---|---|

| SafanDarley EC 3D by Autopol | complete 2D and 3D graphic programming incl. import of 2D and 3D files. |

| Extra Hold To Run operating console | compulsory with 2 machine operators |

Axis / Backgauge System

|

CNC-controlled back gauge | X-axis |

|---|---|

| CNC-controlled 3D back gauge | X1-X2-R1-R2-Z1-Z2 |

| CNC-controlled Delta X-axis | horizontal repositioning of one back gauge finger |

| CNC-controlled Z1-Z2 axis | horizontal repositioning back gauge fingers |

Daylight (Q-Size)

|

27.16 inch |

|---|

| 29.53 inch |

| 31.10 inch |

Tool System

|

NSCL II MC Premium | top tool mechanical clamping system |

|---|---|

| European Style | only in combination with a Q size of 650 mm |

| New Standard NSCL-l HC pro | hydraulic tool clamp system |

Support Arms

|

Fixed support arms (11.81 inch) | standard only for CE countries |

|---|---|

| Moveable front sheet support arms | |

| Moveable front sheet support arms (INOX) with hand wheel adjustment in height | |

| Moveable front sheet support arms (INOX) with pneumatic hight adjustment |

Bending Aids

| SafanDarley I-Mate | maximum plate weight 30kg |

|---|---|

| SafanDarley E-Mate 2000 | maximum plate weight 500 kg |

Measurement Systems

| SafanDarley E-Bend S |

Sheet thickness measurement system (accuracy of ± 0.01 mm) |

|---|---|

| SafanDarley E-Bend L Blue | Laser angle measurement system |

Assessories

| Integrated tool cabinet |

|---|

| Machine lighting |

Offline 3D-programming

The design program includes an ingenious simulation and control module for using the press brake that can be remote-controlled, from the office for example. This limits the time during which the machine is at a stand still, thus maximising productivity.

Offline programming offers you plenty of ways to do 3D Design and to import and correctly produce 3D drawings. If the employee using the program is also the one controlling the press brake, an NC code for the system may be generated instantly. The program will then select the necessary tools and optimise the machine. A work planner can even switch to a different press brake at the last moment, re-generate the NC code and run a collision check.

SafanDarley offline 3D programming stands for complete and reliable process management. As opposed to several widely used CAD/CAM systems, our system is very user-friendly and requires only a short 2-day training period.