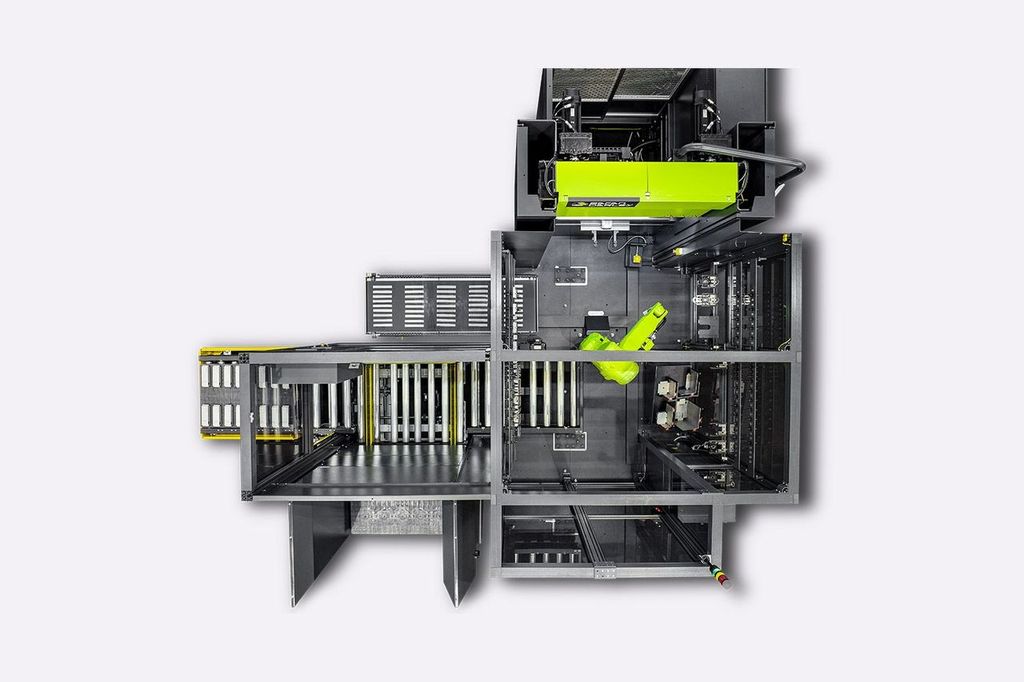

Compact automatic and flexible bending cell

The E-Brake 35T Mini Cell press brake is equipped with a FANUC robot with a handling weight of 25 kg, 2 infeed stations that can be variably configured, a deposit station and a discharge chute. This fully automated press brake is characterised by its compactness.

Optionally, the E-Brake 35T Mini Cell can be equipped with an automatic tool change function. This makes it possible to quickly switch between different products. The ToolFlip function allows tools to be rotated as well.

Since 2023, the E-Brake 35T Premium Mini Cell has been equipped with a double door on the infeed side. This makes it possible to run the Mini Cell for more than 8 hours without human intervention. The addition of an extra product table offers the possibility of doubling the infeed capacity to increase productivity.

There is a wide variety of additional options which can be added to the cell at any time.

As standard, the table stations in the E-Brake 35T Premium Mini Cell are equipped with precision adapters. These adapters guarantee a fixed position, making it possible to have several different tables that can be easily changed. Partly because of this and the application of area scanners in the exchange area, the cell is fully prepared for automatic product/reference table changing by, for example, an AGV, which ensures that the Mini Cell rotates without an operator entering the cell. This makes the E-Brake 35T Premium Mini Cell unique in the market.

Fully electrical driven machine

Fully automatec bending cell

25kg payload Robot

Sheet size up till 600x800 mm

Up to 30% higher productivity

Up to 50% energy saving

No harmful hydraulic oil, low CO2 emissions

Noiseless operation

User friendly touch screen control

Possible to retrofit options at any time

Technical Data

| Model | 35-1250 |

|---|---|

| Pressure force in US Ton | 38,5 |

| Bending length in inches | 49.2 |

| Maximum stroke in inches | 11.8 |

| Q-size in inches | 27.1 |

| Closing speed in inch/min | 425.1 |

| Bending speed max. in inch/min | 16.5 |

| Return speed in inch/min | 425.1 |

| Machine weight in lb | 16.5 |

Standard equipment

SafanDarley E-Brake 35-1250 Premium

SafanDarley E-Control EC10

CNC-controlled R-axis

CNC-controlled Y1+Y2 axis (top beam adjustable inclined +/- 0.1 inch)

CNC-controlled backgauge (X-axis)

CNC-controlled Z1+Z2 axis

Large daylight opening: Q-size 27.2 inch

Top bar fitted with the NSCL-II MC Premium adapter

Lower beam equipped with the hardened OB-II MC table TY adjustment Recessed Q-size of 27.2 inch

FANUC M20iB25 robot with the R-30iA controller and the DCS module

Chute for discharge of small products

1 disposal pallet (31.5x23.6mm)

Safety guard according to the Machinery Directive

Options and Product Enhancements

Assessories & Enhancements

| Programmable offline with RoboBend simulation software |

|---|

| Sheet thickness measuring system |

| Product tables |

| Sheet turnover station |

| Automatic tool changer |

| Tool Flip |

| Automatic gripper changer |

| Extra tool storage |

| E-Bend Check angle measurement |

| Prepared for integration with AGV-systems |

ASC-Control

Automated Solutions Cell-Control is SafanDarley’s software platform for the automated cell. ASC-Control is a very user-friendly and flexible management platform that was born out of the need to allow even employees with little experience to operate automated machines. Fully developed and supported by our in-house software team. The modular structure of the software makes it easy to implement customer-specific requirements and adapt the layout of the cell.

The ASC-Control constantly communicates with the robot and press brake to monitor the status of the entire cell. It tracks every item in the cell and knows exactly where it is located.