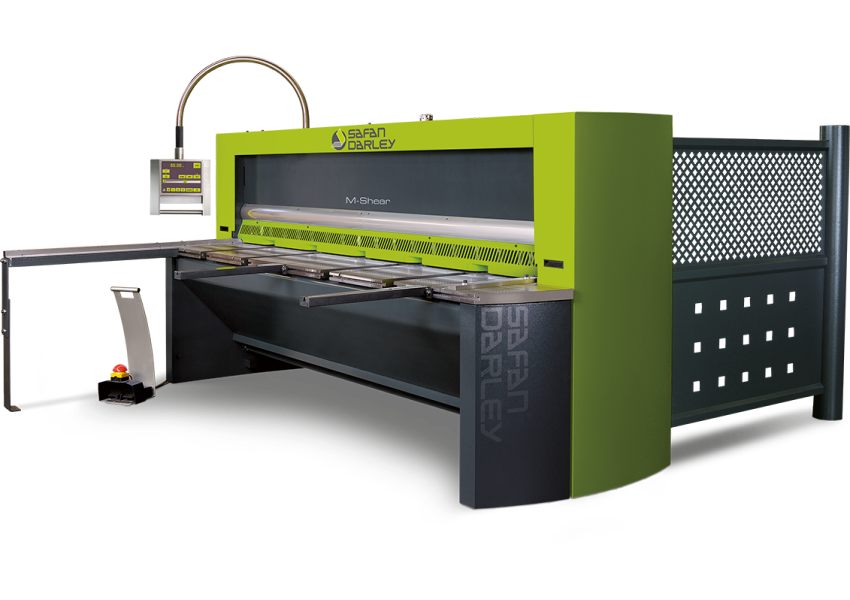

A cut above the rest

SafanDarley makes the premier shear in the market. Our hybrid drive system provides a very precise device with a significant reduction in energy costs.

The M in the M-Shear stands for multifunctional. The advanced hybrid drive system consists of servo electronic motors and a hydraulic pump which produces a remarkably quiet machine that is very energy efficient. This machine is designed with some extremely valuable features such as:

- Programmable start and stop position of the knife bar

- Automatic X-axis compensation when adjusting the cutting gap

- Automatic correction of the stroke length of the knife bar when adjusting cutting angle

Energy saving hybrid drive

Low CO2 emissions

Low noise

User friendly touch screen control

Return-to-Sender sheet support

Torsion free cutting of small strips

Scrap separation

Fully automatic adjustment of cutting angle and clearance

Key Features

Technical Data

| Model | 125-4 | 205-6 | 310-6 | 610-6 | 430-8 | 310-10 | 610-10 | 310-16 | 430 - 16 |

|---|---|---|---|---|---|---|---|---|---|

| Cutting capacity (Mild steel) | 3/16” | 1/4” | 1/4” | 1/4” | 5/16” | 3/8” | 3/8” | 3/8” | 5/8” |

| Cutting length in inches (ft) | 49 (4) | 81 (6.5) | 122 (10) | 240 (20) | 169 (14) | 122 (10) | 240 (20) | 122 (10) | 169 (14) |

| Main motor power in kW | 11 | 11 | 11 | 15 | 15 | 15 | 18.5 | 30 | 30 |

| No. of strokes/min (full cutting length stroke) | 48 | 32 | 24 | 12 | 13 | 12 | 5 | 12 | 8 |

| No. of strokes/min (min. cutting length stroke) | 110 | 84 | 80 | 30 | 30 | 30 | 14 | 34 | 26 |

| Cutting angle 0.5°-max (°) | 2 | 2 | 2 | 1.5 | 1.5 | 2 | 2 | 3 | 3 |

| Backgauge reach in inches | 39.3 | 39.3 | 39.3 | 39.3 | 39.3 | 39.3 | 39.3 | 49.2 | 49.2 |

| Backguage speed in inches/min | 472 | 472 | 472 | 472 | 472 | 472 | 472 | 295 | 295 |

| No. of hold-down pads | 10 | 14 | 20 | 36 | 26 | 20 | 36 | 20 | 26 |

| Machine weight in lb | 8819 | 9260 | 13669 | 41447 | 31967 | 21605 | 61730 | 27558 | 47400 |

Standard equipment

Touch Screen control on movable control arm

CNC-controlled back gauge

CNC-controlled clearance and cutting-angle adjustment

Automatic retraction of the back gauge for narrow strip widths

Programmable start/stop position for the entire length of the cutting beam

Blades with 4 cutting edges

Cutting line lighting with cutting line indication

2 adjustable support arms

2 squaring guides, on the right and left side of the table

T-slots and hand-slots spread across the width of the table

Finger guard

Options and Product Enhancements

Corner Guide

| Adjustable corner guide in grades, 4 90° quadrants |

|---|

Support Arms

| Extended support arms and optional Stops for the support arms |

|---|

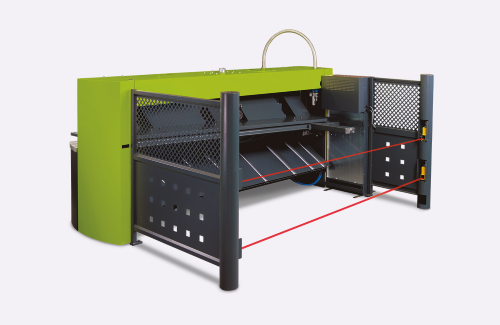

Safety Systems

| Folding finger guard | Finger guard across the entire working length |

| Light screen safety | Light screen safety or folding finger guard |

Table

| Scratch-free table cover | For easy transposition of materials and scratch arms |

| Ball casters in the table | For easy transposition of materials and scratch arms |

Materials Holding

| Pneumatic installation for holding plates up | The pneumatic installation for holding plates up supports the plate to be cut at the back of the shears, making it easy to position it against the back gauge. |

| Fingers for holding plates up in back gauge beam | Fingers for holding plates up in back gauge beam |

| Return To Sender function | Enables you to get more out of your shears, and to cut in a ergonomically responsible way |

Sorting

| Scrap removal cart with our without folding bottom | for small products and scrap |

|---|---|

| Scrap sorter (with/without sorting valve) | for small products and scrap |

Back gauge

| Extended back gauge reach | Entering the cutting size |

|---|---|

| Pneumatic folding back gauge | Entering the cutting size |

Plate removal

| Plate removal with stacker | Support and guidance of the materials to be cut |

|---|---|

| Plate removal without stacker | Support and guidance of the materials to be cut |

ASC-Control

Automated Solutions Cell-Control is SafanDarley’s software platform for the automated cell. ASC-Control is a very user-friendly and flexible management platform that was born out of the need to allow even employees with little experience to operate automated machines. Fully developed and supported by our in-house software team. The modular structure of the software makes it easy to implement customer-specific requirements and adapt the layout of the cell.

The ASC-Control constantly communicates with the robot and press brake to monitor the status of the entire cell. It tracks every item in the cell and knows exactly where it is located.