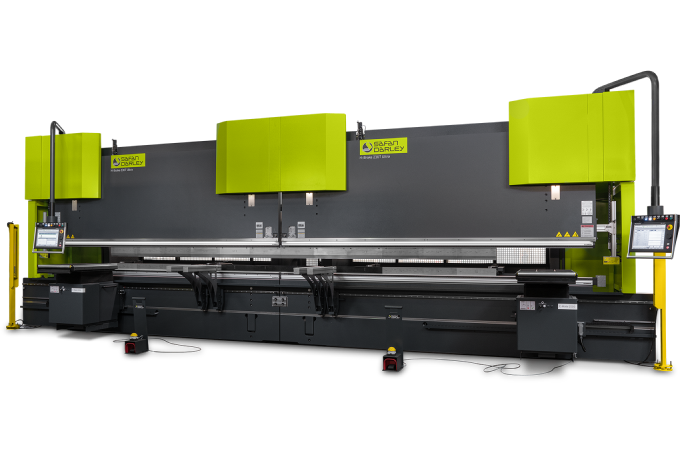

Synchronous bending by multiple machines

Besides the standard H-iBrake series and the H-Brake Heavy Duty series, it is also possible to build a number of press brakes next to each other in tandem, allowing synchronous bending by multiple machines. These machines do not have to be identical. It means that very long products can be bent if more than one machine bends at the same time. It is also possible to bend shorter products using double capacity, the two press brakes then operate separately. Versions and machine options depend on the machine type.

Pressing force from 1250 = 1000 tonns per machine

Bending lengths from 3100 mm to 6220 mm per machine

Heavy-duty backstop version including heavy-duty stop fingers with shock breakers

More than 30% higher productivity

Up to 50% energy saving

Noiseless operation

Key Features

Offline 3D-programming

The design program includes an ingenious simulation and control module for using the press brake that can be remote-controlled, from the office for example. This limits the time during which the machine is at a stand still, thus maximising productivity.

Offline programming offers you plenty of ways to do 3D Design and to import and correctly produce 3D drawings. If the employee using the program is also the one controlling the press brake, an NC code for the system may be generated instantly. The program will then select the necessary tools and optimise the machine. A work planner can even switch to a different press brake at the last moment, re-generate the NC code and run a collision check.

SafanDarley offline 3D programming stands for complete and reliable process management. As opposed to several widely used CAD/CAM systems, our system is very user-friendly and requires only a short 2-day training period.