Highly accurate and lightning fast tool changes

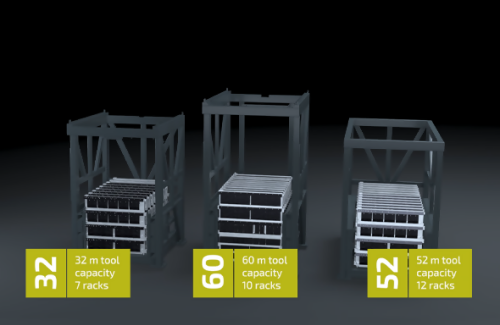

The Tool Mate can be added to several of the SafanDarley press brakes to automate the tool loading for that machine. The tool storage capabilities of 32, 52, or 60 meters of tooling makes this the biggest tool storage available. It is a perfect solution for the client that caters to high mix, low volume orders with complex tool set ups. A unique option is the SafanDarley Tool Mate Twin solution. This allows you to setup your tools from a single storage compartment into two press brakes doubling the effectiveness of your investment.

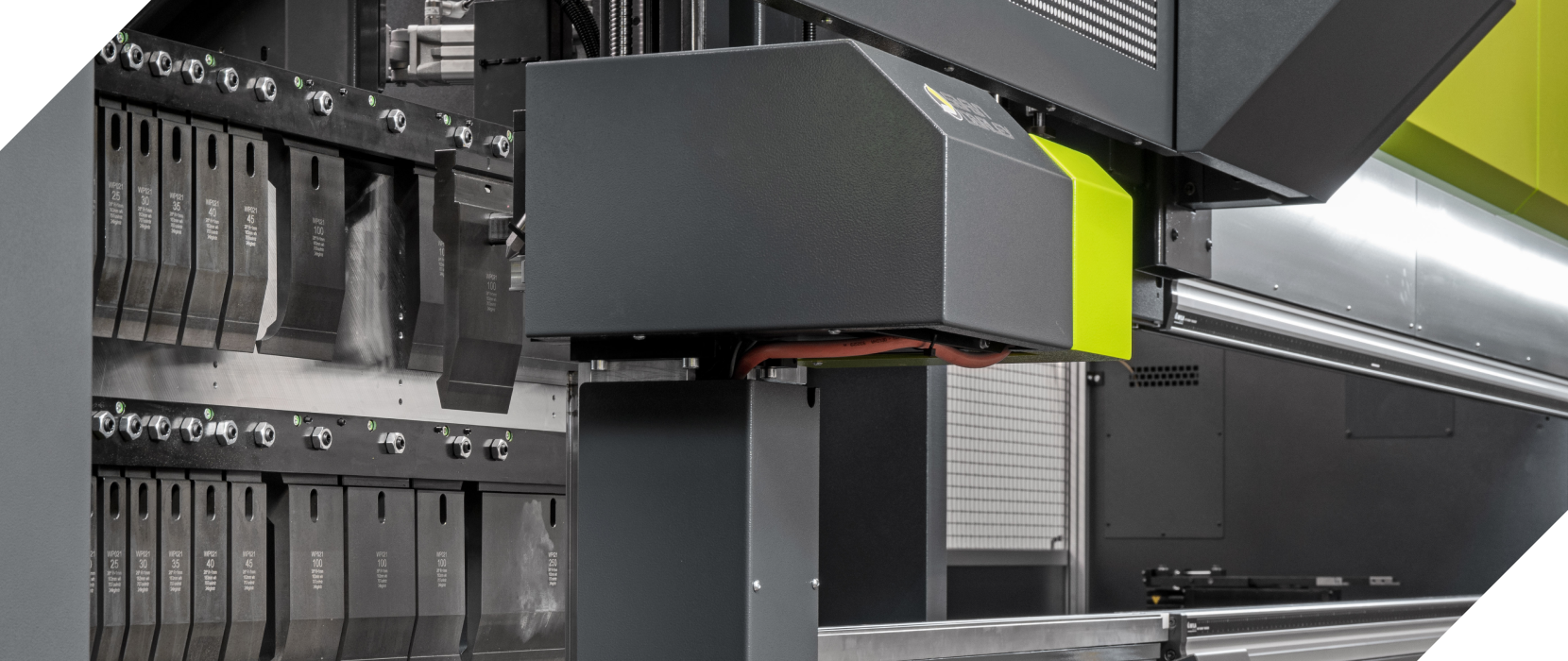

The Tool Mate ensures the automatic placement of the tools in the machine and thus provides extra efficiency and productivity. Whilst the Tool Mate changes tools, other work can be performed. This saves considerable time, especially for small batches. The continuous safety control in the safety zone allows the changer to change the tools at very high speed. For long tool setups, part tools with lengths up to 515 mm can be used.

With a new job, tools are changed automatically, the intelligent software makes only the necessary changes and tools from the previous tool set-up are reused. This results in shorter changeover times and improved productivity.

User-friendly and easy programming

Always fast and correct tool setup

Automatic tool cleaning on return

Rotating station to rotate top tools 180°

Large tool storage capacity: 32/52/60 m

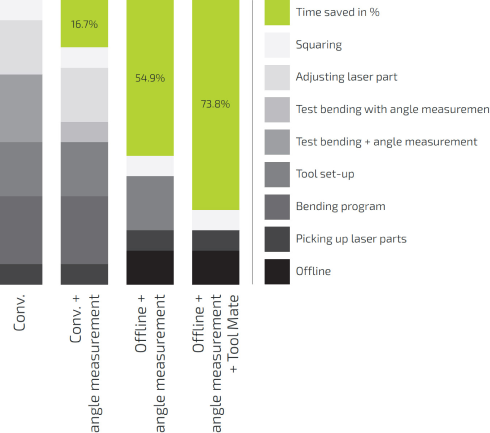

How much time can you save?

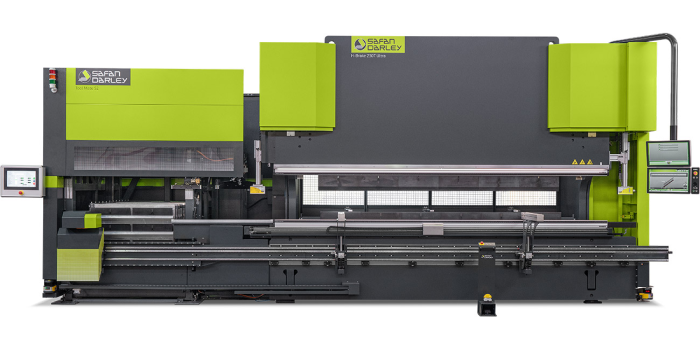

E-Brake C 200T with Tool Mate

Choose maximum sustainability combined with the possibility of fast and efficient production. This servoelectric E-Brake C with 200T pressing force has a working length of 4335 mm and is equipped with a 250 mm C-frame that makes it possible to change tools sideways.

The SafanDarley Tool Mate is one of the largest CNC-controlled tool storage systems for press brakes on the market with the greatest flexibility of use. It is the perfect solution when working with high-mix, low-volume orders with complex tool set-ups in today’s modern production environment.

H-Brake up to 320T with Tool Mate

Choose maximum flexibility by combining the Tool Mate with our sustainable hybrid or high-end hydraulic press brake. The Tool Mate can be placed either on the left or the right of the press brake. It is also possible to opt for a Twin set-up in which the Tool Mate is used for two press brakes.

The Tool Mate - Single or Twin – is the perfect combination of process automation and increased production capacity. Compared to manual configuration, the Tool Mate can significantly reduce the set-up time.

Key Features

Technical Data

| Model | Timings |

|---|---|

| Loading time for long tools punch length >= 125mm, die lenght >= 250mm | 4 sec. |

| Loading time for short punches | 8,5 sec. |

| Loading time for short dies | 8 sec. |

| Unloading time for tools | Loading time + 1 sec. |

| Axes parameters | Max. speed (m/s) | Max. acc (m/s^2) |

|---|---|---|

| XC Axis | 0,57 | 0,3 |

| RC Axis | 0,38 | 0,8 |

| ZC Axis | 3,24 | 8 |

| AC Axis | 1,19 | 20 |

| VC Axis | 0,40 | 1 |

| X2C Axis | 0,21 | 1,5 |

Standard equipment

Tool Mate 32 meters, incl. 7 tool racks: 4 for V-dies/3 for punches

Tool Mate 52 meters, incl. 12 tool racks: 7 for V-dies/7 for punches

Tool Mate 60 meters, incl. 10 tool racks for both dies and punches

Very fast tool configuration: tool length 20 to 515 mm (max. 40kg)

Large operating range: V-dies 5 mm to 70 mm

Laser check tool position to minimize risk of errors

ASC-Control

Automated Solutions Cell-Control is SafanDarley’s software platform for the automated cell. ASC-Control is a very user-friendly and flexible management platform that was born out of the need to allow even employees with little experience to operate automated machines. Fully developed and supported by our in-house software team. The modular structure of the software makes it easy to implement customer-specific requirements and adapt the layout of the cell.

The ASC-Control constantly communicates with the robot and press brake to monitor the status of the entire cell. It tracks every item in the cell and knows exactly where it is located.